| Model | Capacity(kg/h) | Power(kw) |

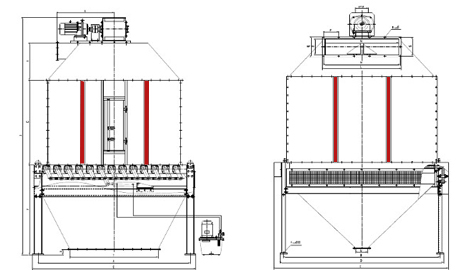

Function and application |

| LM-LS50 | 400-600 | 8 | The cooling screen separator is a special equipment for cooling and sorting particles. It is suitable for the screening of various feed, wood pellets and other materials. It has high screening efficiency, low noise, small dust volume and long service life. simple maintenance, simple operation and so on. It is used for cooling of poultry animal feed with bag dust removal, used for feed production line below 1 ton. |

| LM-LS90 | 800-1000 | 8 |