.jpg)

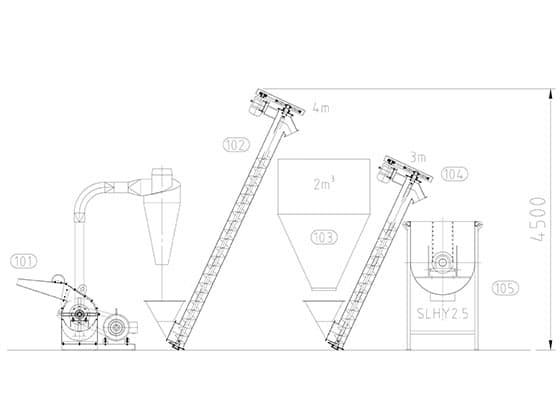

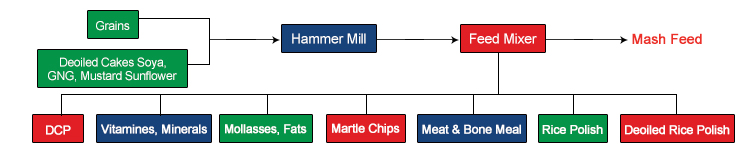

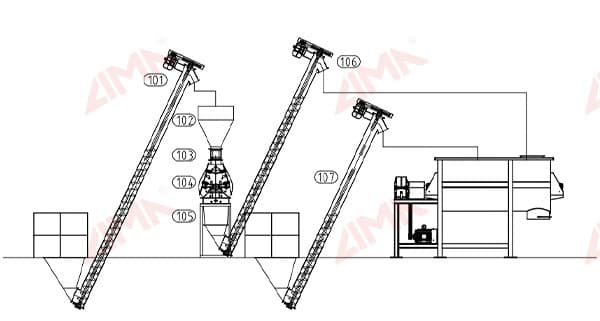

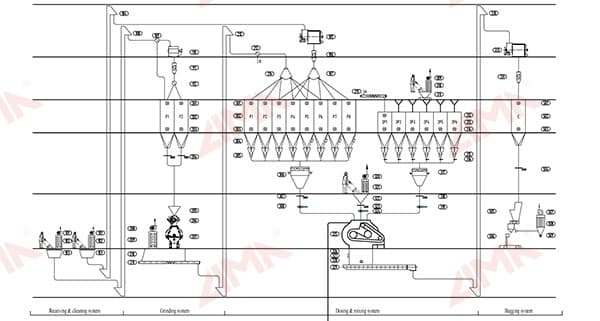

In a mash feed plant, all kinds of raw materials go into raw materials warehouse after crushing and carried out in accordance with the formula is controlled in the automatic control on the raw material ingredient. at the same time put in premix, finally in the feed mixer for mixing, mixing time according to the size of capacity of mixer, and the actual situation of the feed production to determine, regularly test mixing uniformity, in order to adjust the mixing time. The mixed feed will be transferred into the mash feed warehouse, sealed and shipped into the finished product warehouse.

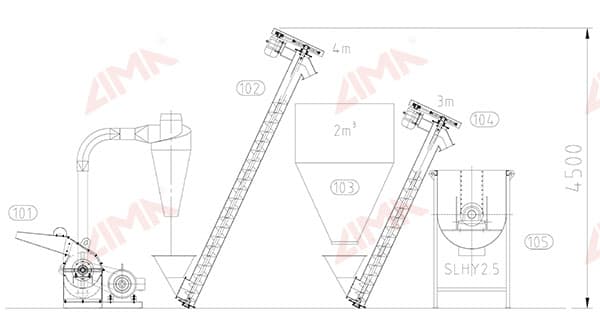

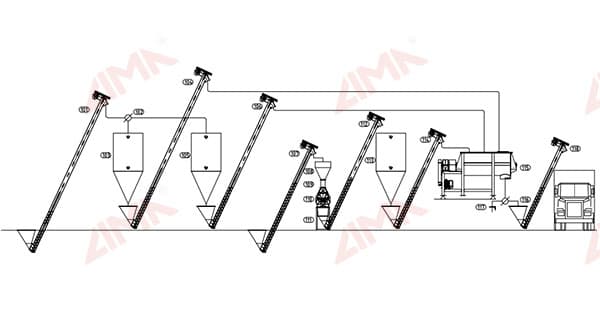

This mash feed production plant including receiving & cleaning system, grinding system, dosing & mixing system, and bagging system.

Can be customized according to your detail requirement.

We can build the complete turnkey mash feed & feed pellet plant. More efficient, more energy efficient, more reasonable, low price.

| Model | Capacity (ton/batch) |

Power (kw) |

| SESP56-36 | 3–5 (3mm mesh) | 22/30 |

| SESP56-40 | 6–7.5 (3mm mesh) | 37/45 |

| SESP66-60 | 9–12 (3mm mesh) | 55/75 |

| SESP66-80 | 15–18 (3mm mesh) | 90/100 |

| Model | Capacity (kg/batch) |

Power (kw) |

| SSHJ-0.5 | 250 | 5.5 |

| SSHJ-1.0 | 500 | 11 |

| SSHJ-2.0 | 1000 | 18.5 |

| SSHJ-4.0 | 2000 | 30 |