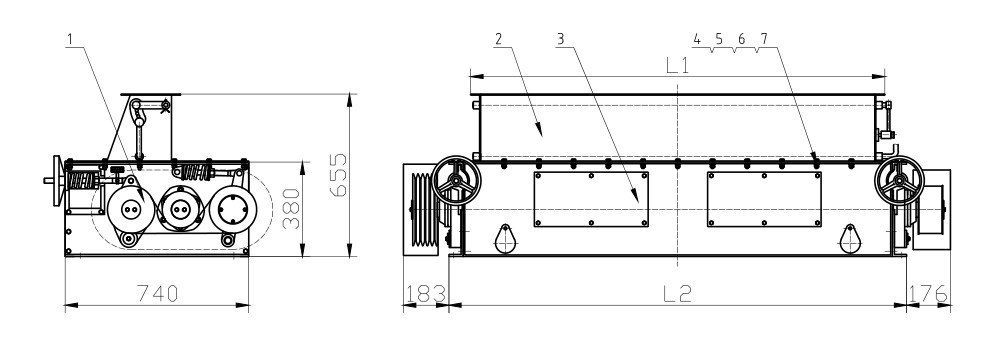

| Model | Capacity(T/H) |

Function and application |

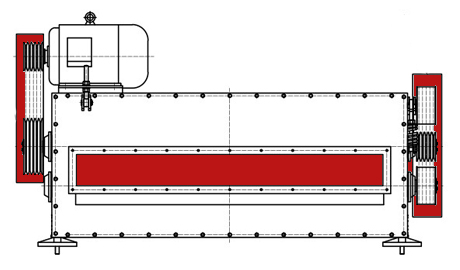

| SSLG15*80 | 1-3 | For crushing feed pellets to make chicks feed. 1. It can crush various specifications of granular materials into 0.6-1.5mm or 1-2.5mm particles; 2. Compact structure, uniform crushing, convenient and fast particle size adjustment; stable transmission, low noise, reliable operation, and convenient operation, making the feeding more continuous and stable, the particle size of the finished product more uniform, and the efficiency is high. 3. The rolls implement differential rotation speed, and the pellets are squeezed, sheared and torn between the two rolls, so as to achieve a good crushing effect. 4. The unique feeding hopper and bypass device not only play the role of homogeneous material, but also play the role of bypassing the materials that do not need to be crushed. When the bypassing flow is used, the travel switch can automatically stop. |

| SSLG15*100 | 4-6 | |

| SSLG15*150 | 3-8 | |

| SSLG20*170 | 15-20 | |

| SSLG25*170 | 20-25 |